Demanding customer application

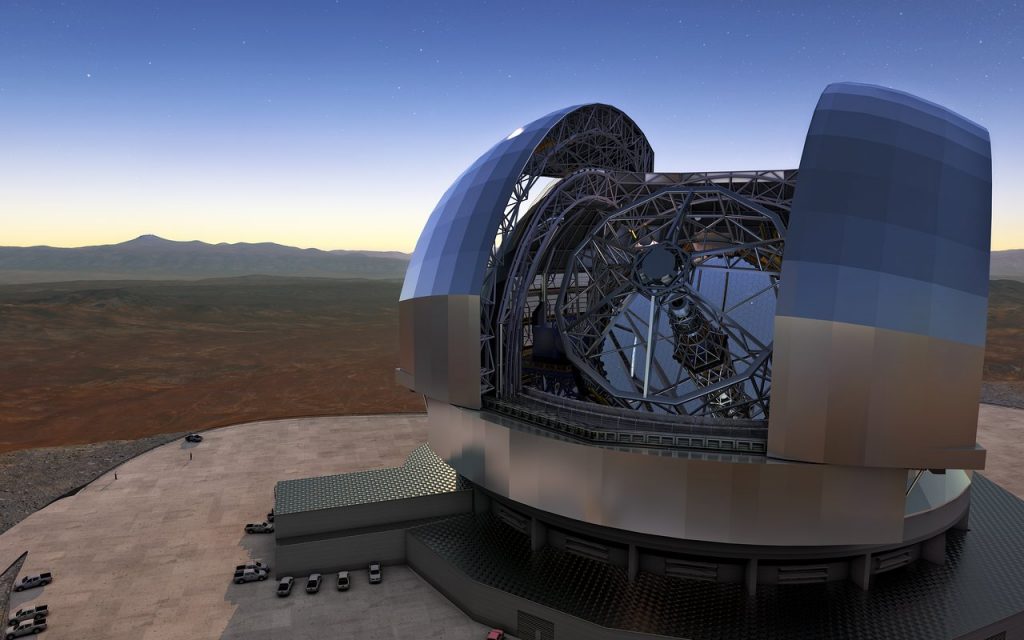

Dutch company VDL ETG Projects is building the supporting structure for the main mirror of the ESO ELT in northern Chile. At an elevation of over 3,000m in the Atacama Desert, the ELT will enable new scientific discoveries related to planets, the composition of nearby galaxies and the deep universe.

The supporting structure consists of 798 individual support structures for mirror segments, each 1.4m across and driven by multiple electric motors to optimize precision. The telescope’s main mirror will have a diameter of over 39m to gather 100 million times more light than the human eye, and 13 times more light than the largest optical telescopes in 2014.

A total of around one billion Euros has been made available for the ELT project. The telescope will be operational in 2024.

The need for a beyond-standard solution

“Initially standard stainless steel bolts where incorporated into the design of the ELT project but our calculations and tests showed that they lacked strength in some extreme situations,” says Michael Evers, Project Manager at VDL ETG. “We required a 10.9 strength bolt, but with the corrosion resistance of stainless steel. BUMAX offered us the perfect solution.”

The BUMAX solution

The BUMAX fasteners are used to fix the telescope mirrors to their segment supports. The ELT uses 12 10mm long BUMAX® 109 M6 bolts per segment and there are a total of 798 segments, plus an additional 133 segments for a continuous swapping process to allow the mirrors to be coated while the ELT stays operational.

The 10 mm long M6 bolts were a customized product that required special tools to manufacture. Following a request from the customer, the bolts were also coated with Dicronite® to minimize friction. Dicronite coating is a common surface treatment for fasteners used in telescopes, but it was the first BUMAX product to be treated in such a way.

“The high strength BUMAX 109 fasteners prevent damage to the mirror segments, which are very costly,” explains Evers. “Their corrosion resistance is also essential as the fasteners are sometimes open to the elements and will reduce future maintenance requirements.”

For more information about the ELT:

https://www.eso.org/public/teles-instr/elt/