OPUS Aerospace was formed in 2019 to provide cost-effective launch solutions for nano-satellites, micro-satellites and mini-satellites. It aims to offer sub-orbital commercial launch services by 2026 and ultimately orbital services.

“We already offer our customers various space systems services and are currently conducting pilot tests for the different parts of our new fully reusable rocket,” explains Safouane Benamer, CEO of Opus Aerospace. “We’re planning a test launch of our Mesange rocket in early 2024, which will pave the way for us to launch sub-orbital payloads of up to 1,000 kg and orbital payloads of 250 kg. We’ll scale up our offering step by step.”

Meeting the needs of critical rocket applications

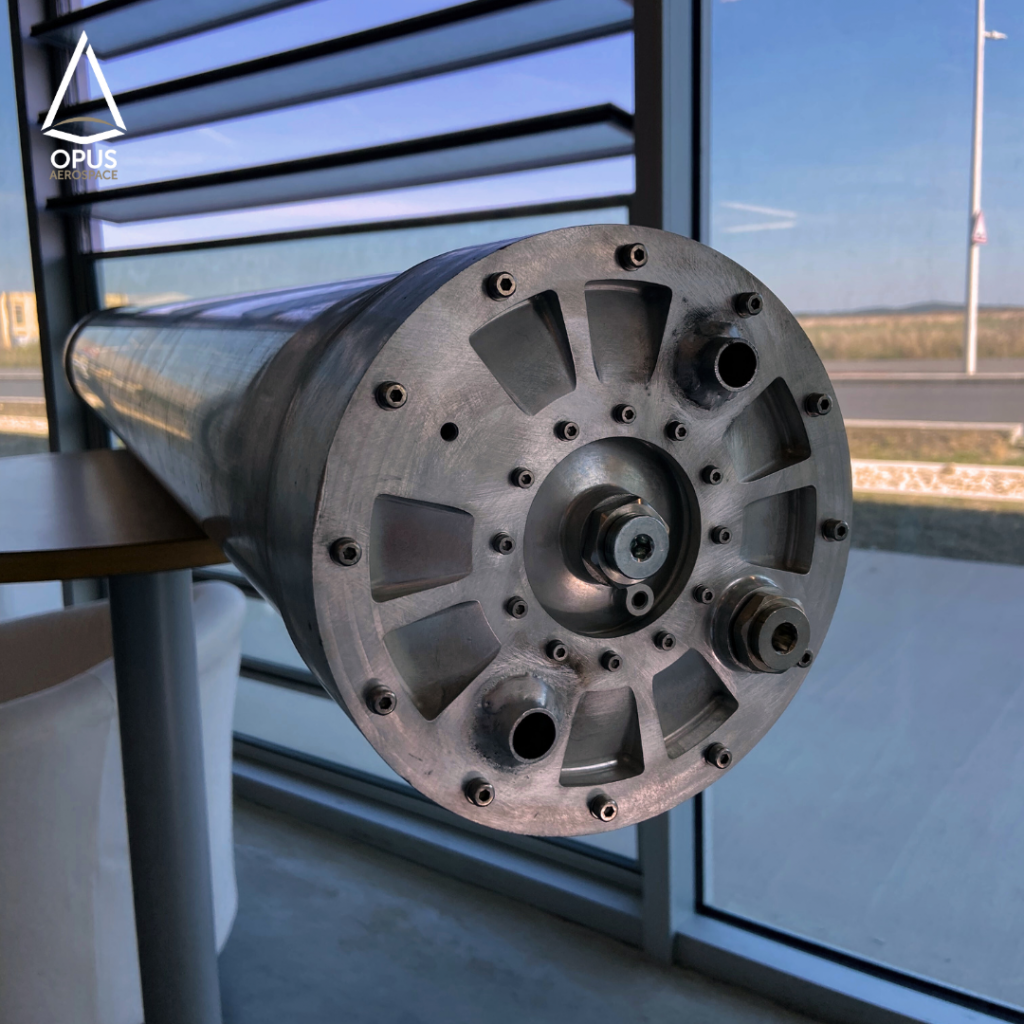

OPUS Aerospace is using BUMAX® 88 screws to secure the two domes of a prototype cylindrical fuel tank for the Mesange suborbital rocket. The domes must have high-strength screws as they are a critical part of rocket with extremely high pressure.

“Our initial calculations showed that standard stainless steel fasteners simply wouldn’t cope with the loads,” says Ignacio Amundarain, Launcher Mechanical Engineer at OPUS Aerospace. “We have already tested and validated the design of our fuel tank with BUMAX® 88 on the ground with even more demanding pressurization tests than we can expect in normal conditions. We are confident that this will ensure the safe operation of our fuel tank.”

OPUS Aerospace has obtained an excess supply of BUMAX® 88 that will be used for other important applications on the prototype rocket. These include securely fastening the fuel lines from the fuel tank.

Excellent reliability and quality

Besides high strength, BUMAX® 88 screws offer excellent reliability and quality with consistent properties. They also provide corrosion resistance, which is important for a reusable rocket that may be exposed to the elements and potentially seawater.

“I know how reliable BUMAX are from my previous job of designing satellites,” says Amundarain. “They are also cost effective compared with other fastener solutions with similar premium properties.”

The BUMAX® 88 screws were provided with a 3.1 certificate, which confirms that they were fully tested in accordance with DIN-EN-10204 and that they are manufactured in compliance with the order specification. This ensures excellent quality and traceability.

“We are very pleased with the level of service from the BUMAX support team who advised us on our product selection and design, and dealt with the order and delivery,” concludes Amundarain. “We are looking forward to continuing our rocket development journey together with BUMAX.”

The enhanced properties of BUMAX® 88 fasteners are achieved through a combination of unique BUMAX manufacturing processes and the highest quality European steel. BUMAX® 88 fasteners are also certified according to DIN EN 15048-1 (Non-preloaded structural bolting assemblies) and to meet requirements in accordance with PED 2014/68/EU (Pressure Equipment Directive).